Last year I bought a smallblock Mopar 360ci engineblock and started working on rebuilding it for my daily ’73 Dart, in favor of the current 318.

The plan is to build an efficient running engine that can put out some good mileage and power.

The current 318 engine with its 8.6:1cr engine/drivetrain combo cannot provide better mileage then 10-11mpg on daily (summertime) commuting. Winter mileage is a sad 8mpg orso. It does get 15mpg on highway (summer) trips.

I’ve spend a lot of time reworking the ignition timingcurve, mixture adjustments, cool air intake and oil weight tests, but the car just doesn’t get any better mileage. The car is certainly fun to drive and the engine, with it’s 22″ vacuum at idle it’s very responsive.

But I hope to get some considerable better mileage with a more efficient, high cr 360 engine.

The 318 in my Dart has some camshaft or intermediate shaft wear, which does a funny thing with the timing at low rpms.

When setting the idle-advance at say 15°, it will decrease to about 10-12° for the first few 100 rpm’s as the engine rpms go up, after which the mech.advance will kick in and start increasing timing again. I think the intermediate shaft is probably riding up on the camgear or something causing this timing issue.

Since my daily commutes are also pretty much all 15-20min. Stop&Go driving with a cold engine, mileage doesn’t stand much chance.

The 360 engine came with high compression ‘107’ KeithBlack pistons and by using closed chamber swirlport ‘302’-heads, a static compression ratio of 10.5 to 11:1 should be possible. Still have to decide where I want to end up with the CR. Will need to do some dynamic compression calculations soon.

The engine wasn’t complete. I had to locate a crank, heads, camshaft, rockers and a number of other items to make it complete.

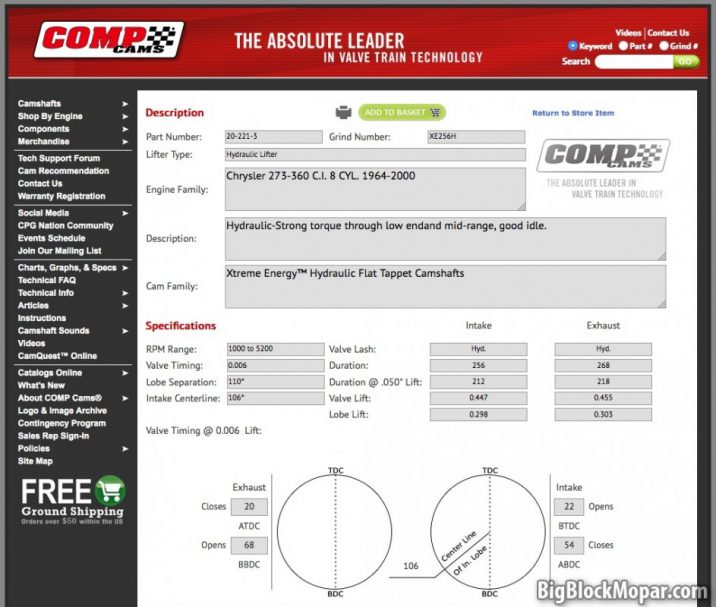

I’ve just purchased a freshly reground crank @ .010″ under, and also ordered a XE256H CompCams camshaft along with 1.6 ratio roller rockers. I still have some worries if the ‘Extreme Energy’ camshaft might build too much cylinder pressure which would increase chances of detonation with the ‘mild’ cam.

Although I do like the lopey idle of a higher duration cam, it didn’t make much sense (with mileage in mind) to choose a bumpstick with it’s active working rpm-range outside the engine’s daily rpm-range between 600 and 3500 rpm.

Also would rather have liked to install a roller cam in this engine but didn’t want to blow the bank on this build yet. Maybe sometime later.

I’ve had the heads milled and new bronze valve guides installed. Next will be portmatching the exhaust ports and polish the chambers as smooth as possible with the tools I have available, mainly to reflect and keep heat out of the castiron heads.

After a good number of hours of (tediously) polishing and grinding away at/in the ports, removing sharp edge and protruding metal which could hinder flow and contouring them, the heads were finally done.

Here I smoothed out the intake and exhaust ports and blended the castinglines and ridges.

Tried polishing the chambers to a mirrorlike shine (to prevent carbon build up and reflect combustion heat back into the mixture and not into the head) but that took quite a bit of work and didn’t turn out as shiny as I hoped for.

I scribed the edge of the cylinders onto the heads and unshrouded the valves close to that line.

The picture on the right shows the heads completely reworked.

Leave a Reply