In September 1998 I started the rebuild of this 440 engine.

440ci (1966) w/ 0.030″ overbore.

‘915’ heads w/ home port&polish.

2.08 / 1.74 MP valves.

KeithBlack Hypereutectic Pistons (237), zero-deckheight.

0.040″ piston/head clearance. 11:1 cr (measured).

Erson Solid cam (256@050, w/ 0.534 lift) 2 deg. advanced. Crower Solid Lifters.

Crane 1.5 Gold Roller Rockers.

Edelbrock Double Roller Timing Chain.

Edelbrock Torker (old) intake manifold (Dual quad Offenhauser intake in photos).

High Volume Oilpump with stock pan w/Mopar Performance windage tray and extra drainback-holes.

Moroso 11mm ignition cables.

Stock LY-rods. ARP bottom end.

Stock forged crank w/ org. bearingsizes.

Fully balanced assembly.

—————

During a dragrace-weekend with the engine installed in the ’71 SuperStreet Dart I got distracted in between the runs while I was resetting ignition advance timing and also fiddling with the carb.

As a result the engine pinged during the next run and broke the ringland of a piston and the loose part in the chamber caused the piston to tumble hard enough to crack the cylinder wall.

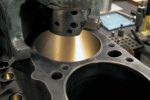

Decided to install a cylinder repair sleeve to save the engine block.

The cylinder was bored to about ±4.50″ and the sleeve was pressed in until it rested on the small ridge at the bottom of the cylinder we left unbored.

After installation, the sleeve was tested on roundness and a thin skim-bore was done in the cylinder.

We found however the sleeve had deformed a bit to the shape of the cylinder were the cylinder bore didn’t hit the sleeve. But after another light bore to sleeve was touched all around and the sleeve was taken to .030″ overbore to match the rest of the engine again.

A new Keith Black piston was installed and the engine reassembled again.

—————

440ci engine rebuild again